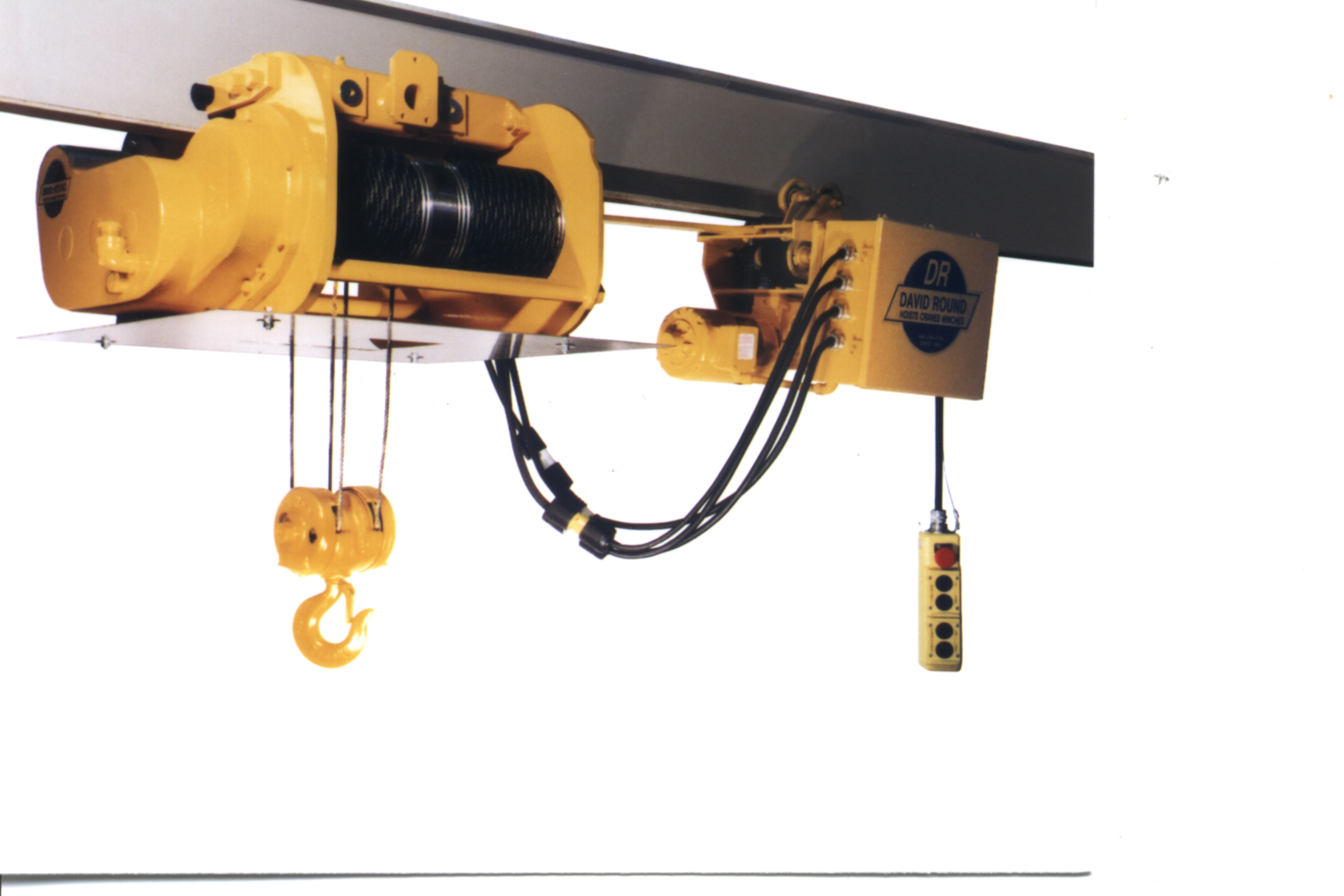

David Round Hot Metal Wire Rope Hoist

Designed with the assistance of foundry managers and casting line personnel, David Round’s line of hot melt hoists sets the standard for ladle handling hoist in manual and semi-automatic metal casting operations. David Round’s hot melt hoists exceed industry expectations are built exclusively for safe and heavy-use in harsh foundry environments, unlike other hot melt hoists that are simply de-rated, higher capacity standard hoists with a few bells and whistles.

Product

Share

David Round’s hot melt hoists are available as standard units in capacities up to five tons. In addition to meeting required design factors, limit switch and other safety mandates, David Round’s hot melt hoists are equipped with a long list of standard features including low-headroom designs, true vertical lift, NEMA 4 enclosures, power disconnects, thermal overload relays and 60-minute class “H” motors.

- Standard models lift up to 5 tons

- Built to exceed accepted hot melt hoist standards and specifications

- Rated for H-4 hoist duty

- 8:1 Minimum design factor on all critical components including the wire rope

- Double-braking low-headroom design features true vertical lift

- Various suspension packages are available including push and motorized trolleys, tractor drives and articulating hoist carriers for patented track

- Custom and larger units available

- All products are available in Stainless Steel and Made in the U.S.A.

SUMMARY OF FEATURES

- 8:1 wire rope minimum design factor

- 8:1 critical hoist component design factor

- 6 x 37 wire rope with I.W.R.C.

- AC disc style motor brake

- Weston style roller ratchet mechanical load brake

- Upper paddle style power circuit limit switch

ADDITIONAL FEATURES

- Rotary limit switch for upper and lower hook stops

- Visual alarm / beacon

- Integrated trolley frames with restraining lugs

- Rubber trolley bumpers

- Mainline disconnecting contactor with on/off buttons

- H-4 hoist duty

- True vertical lift

- Low headroom design

- Hoist-duty 60-minute motors

- Class “H” motor and brake installation

- Heat shield

- High temperature wiring

- NEMA 4 hoist control enclosure

- NEMA 3R push-button pendant with E-Stop

- Thermal overload relays

- 110 volt low current control signal circuit

OPTIONAL FEATURES

- Choice of push trolley, motorized trolley or tractor drive

- Variable speed hoist control with AC inverter drive

- Soft start and variable speed trolley upgrades

- NEMA 4 manual disconnect switch

- Pendant outrigger

- Collector arm mounting bracket

- Articulating hoist carriers for curves and switches

- Flangeless wheels with guide rollers

- Remote-mounted electrical enclosures

- Twin hook hot melt hoists

- Air-powered hot melt hoists

Related products

Our Service Areas

St. Louis, MO Area

Kansas City, MO Area